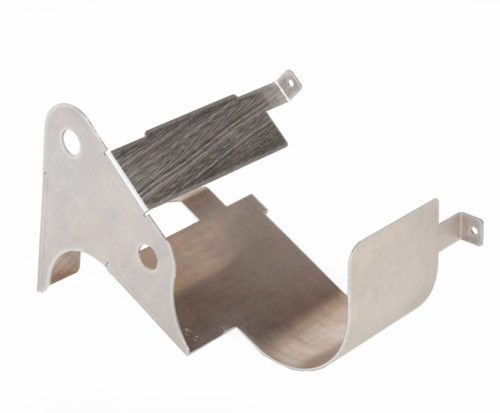

This barcode printer label catcher was fabricated here at Pyramid Fab and Finish, and it demonstrates our ability to create multiple complex angular and rounded bends to meet specific product requirements.

This barcode printer label catcher was fabricated here at Pyramid Fab and Finish, and it demonstrates our ability to create multiple complex angular and rounded bends to meet specific product requirements.

Constructed from 0.050″ thick aluminum sheet, primary operations consisted of bending, punching, and spot welding to form the precise geometries, and assemble the components. In addition a grained finish was also required, as well as deburring. The completed parts featured overall dimensions of 9.0″ x 7.0″.

Having the right tooling, equipment, and a skilled workforce has enabled us to produce these parts with the outstanding quality the customer was looking for. We currently fabricate them in lots from 100 to 5000 units for delivery within a four week timeframe.

If you are interested in learning more about this project or any of our fabrication services, contact us today.